iBulk® offers a broad range of specialised Bepex® agglomeration and compaction equipment to meet your specific needs for bringing finely divided bulk solid material into a larger form..

iBulk® offers world class agglomeration and compaction equipment and know-how. Understanding the process requirements and leveraging our experience with a broad range of agglomerating applications is the best way to design an optimised agglomeration process. Our equipment will suit all your agglomeration and compaction needs.

Our Roll Compactors, for example, are suitable for powder compacting into high-density granules where moisture addition and binders are undesirable, and our Briquetters produce uniform size and shape particles.

For processes that require an agglomerate suitable for rapid dissolution, iBulk provides high-speed industrial mixers that create porous granules for instantising applications, as well as low-pressure extrusion resulting in robust pellets that offer more controlled dissolution in liquid.

Based on our extensive, 30-year experience and a thorough understanding of our customers’ needs we help you select the best option of agglomeration technology solutions for optimised performance and value.

SIZE REDUCTION EQUIPMENT INCLUDE

iBulk provide the industrial process equipment solution to meet your needs:

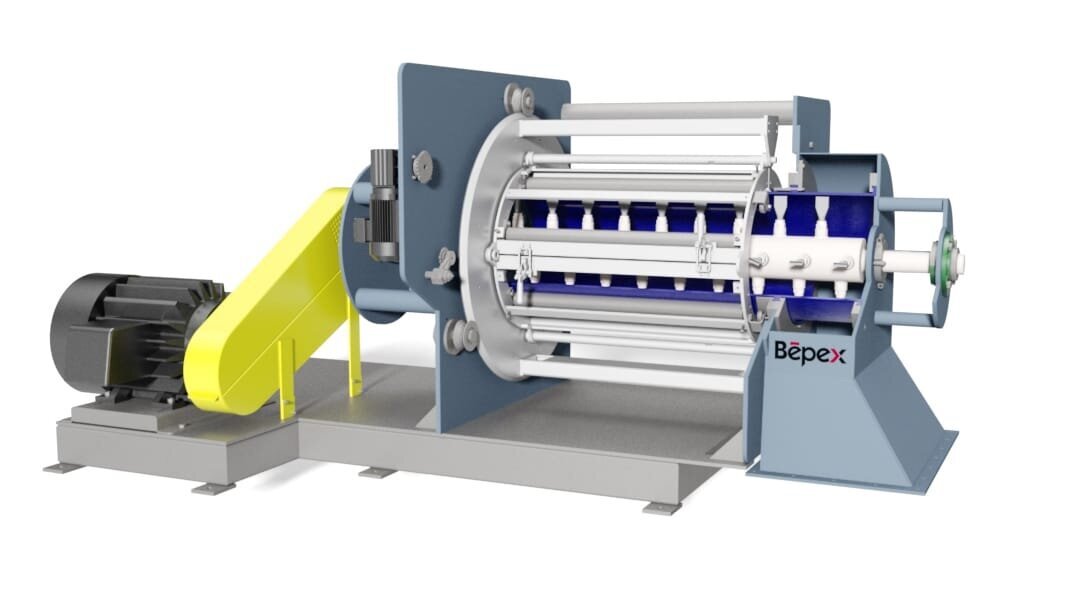

MS Roll Compactor – ideal for producing hard, dense sheets, granules, or briquettes

Turbulizer Paddle Mixer – a high shear paddle mixer for low-moisture agglomeration and coating

Extrud-O-Mix Extrusion Machine – a low pressure extruder for mixing and forming large agglomerates in a single step

FlexTurbulizer Mixer Agglomerator – self-cleaning, mixer agglomerator for production of robust lower-density granules

Our agglomeration equipment is designed to be customised to your process. We test these options at the Bepex Process Development Center, allowing us to create custom agglomeration machines and systems tailored to your application.

At iBulk we understand that requirements change over time and our process engineers provide on-going process optimisation and aftermarket services.

With our technology and extensive material process experience, we have the tools to design complete industrial process systems for your application.

TYPICAL APPLICATIONS AND INDUSTRIES

Typical applications for iBulk Agglomeration and Compaction Equipment:

Instantising of food mixes

Pre-conditioning of agglomerates for final shaping

Reprocessing of out-of-spec fines for saleable use

Forming of food and chemical products

Dedusting of fine particles for improved shipping and handling

Fertilizers and Ag Related Materials

Feed Additives

Polymers

Low Density Minerals

Clay

Sweeteners

Water Treatment Chemicals

Salts

Metal Oxide and Carbonates

Metal powders and shaving

Steel processing byproduct streams

Fuels like charcoal or coal

Refractory materials like magnesium oxide or dolomites

Fluxing materials like calcium oxide

And others.