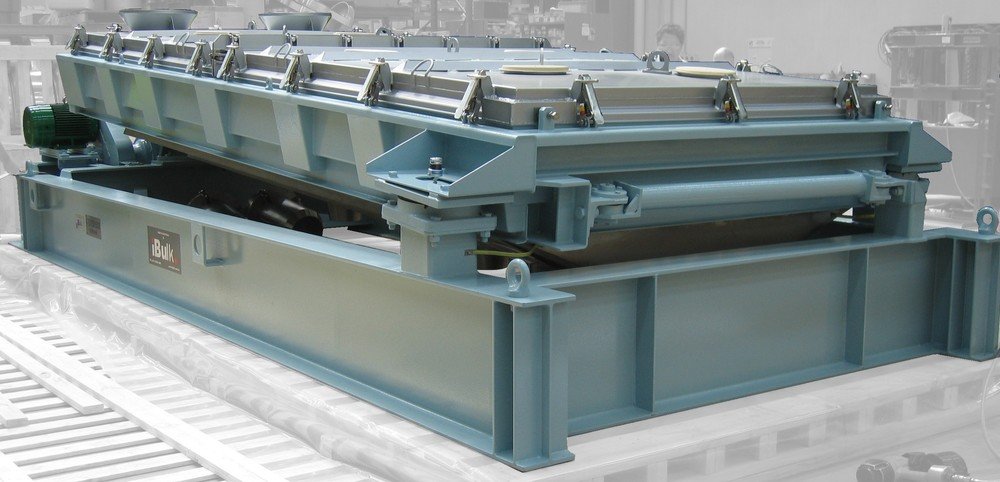

Rotex Gyratory Screener

Meet the machine that launched an industry.

Precise. Rugged. Versatile. The ROTEX® industrial screener with automatic tensioning delivers on-spec products with less rejection of good materials for increased profits. ROTEX® endures today as the industry standard, thanks to countless applications in the toughest conditions around the world.

Gyratory Reciprocating Motion

Gyratory motion rapidly distributes, stratifies and separates. This unique gyratory motion pattern imparts a combination of actions to the material as it passes along the screen surface. It begins with a horizontal circular motion at the feed end, gradually diminishing along the length of the machine to an elliptical path, and finally to an approximate straight-line motion at the discharge end. There is no vertical component to this motion – thus keeping the material in constant contact with the screen surface.

DISTRIBUTES: Circular Motion at the Feed

The gyratory motion at the feed side of the machine immediately spreads the material across the entire width of the screen surface to maximise screen utilisation. At the same time, this motion stratifies the material, causing the fines to sink down against the screen surface. The particles that are appreciably smaller than the openings quickly pass through at this part of the screen.

STRATIFIES: Changing to Elliptical Motion at the Centre

As the circular motion diminishes into an elliptical path, the gentle near-horizontal motion causes the fine particles closer in size to the screen mesh – the near-size particles – to fall through the mesh openings.

SEPARATES: Straight-Line Motion at Discharge End

The nearly linear reciprocating motion at the discharge end of the iBulk Rotex Screener removes those particles closest in size to the mesh openings while gently conveying the oversized material off the screen. In addition, the unique iBulk Rotex ability to advance or retard material flow at the discharge end allows further separation fine-tuning to achieve the most efficient and accurate motion for the application.

Installation

The Rotex range consists of floor-mounted and suspension options.

Floor Mounting

Because the Rotex® counterbalanced drive has low transmitted forces, the Rotex can be floor-mounted in properly designed structures, a unique feature of this type of equipment.

Cable Suspension

Rotex® Screeners can be cable-suspended from the four corners of the machine, thereby isolating screening forces from the surrounding structure. Note that certain Rotex® models can only be cable-suspended.

Advantages

Lower headroom permits operation in confined areas, reducing the cost of building construction and maintenance.

Less conveying equipment is required for elevating the material to the feed point.

Automatic Screen Tensioning

Easy Screen Removal

Applications and Industries

Rotex Screeners operate at hundreds of locations and screen literally thousands of different materials. While not all-inclusive, the following list details some industries and applications where Rotex is the screener of choice.

Abrasives

Carbon Products

Clay

Food products: like sugar

Pharmaceutical Applications

Grain Cleaning

Paper Pulp Chips

Plastic Pellets

Rubber Recycling